Bridging the gap between groundbreaking research and real-world manufacturing

What we do for you…

-

We collaborate closely with our clients to truly understand their vision, combining our expertise in engineering and design to develop breakthrough concepts that are both practical and innovative. We guide you through the early stages of product development—delivering unique, manufacturable concepts ready to take to the next level.

-

Once the concepts have been created and developed we turn the idea into something real. This involves detailed engineering, developing how the product will be manufactured, tested and assembled. This takes a number of stages; first prototype, production candidate, final design.

Prototypes are made along the way and regular reviews held to ensure we're meeting your expectations.

-

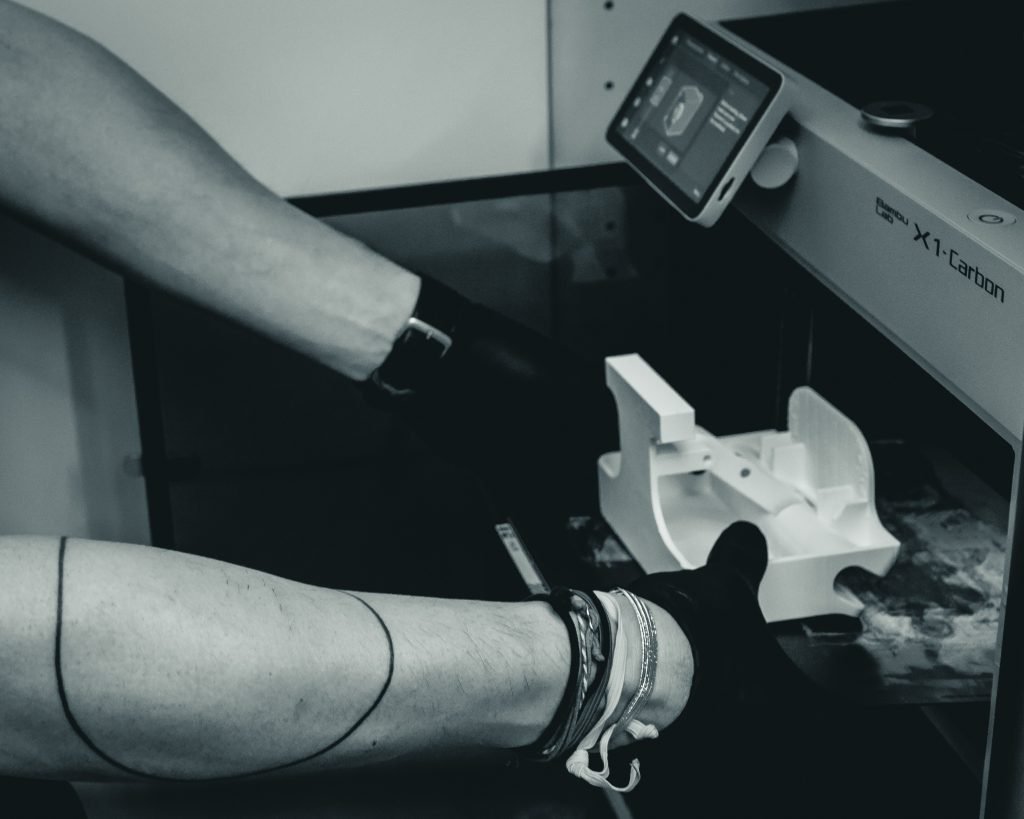

We are proud of our in-house prototyping capabilities which allow us to quickly transform concepts into tangible products. We can produce high-quality same-day prototypes that enable real-world testing, refinement, and validation. From early-stage mock-ups to fully functional models, we offer precision and efficiency at every step, accelerating the development process and allowing us to refine designs and resolve potential challenges before moving into full-scale production.

We also work with a handful of excellent suppliers to produce what we cannot do ourselves.

-

Through years of hands-on experience, our project management skills ensure the smooth execution of every design project. By staying agile, adaptable, proactive, and detail-oriented, we work closely with you to meet your goals, ensuring projects are delivered efficiently and effectively from concept to completion.

-

We understand that successful product design is only as strong as its manufacturability. Our knowledge of materials, production techniques, and supply chains allows us to create designs that are not only cutting-edge but also practical and cost-effective to manufacture.

We can source custom components, including complex and intricate parts (eg. optically bonded LCDs) injection moulds, PCBs, packaging and full assembly.

-

At Relay Industries, we offer comprehensive electronics and software design as part of our product development services. From PCB design and firmware development to embedded software and system integration, we collaborate with expert partners to deliver cutting-edge electronic solutions that seamlessly complement our mechanical and industrial designs. Whether you're developing a smart device, IoT system, or complex electromechanical product, we ensure innovation, reliability, and manufacturability at every stage.